PRODUCTS

ANSI CENTRIFUGAL PUMPS

ANSI CENTRIFUGAL PUMPS

ANSI CENTRIFUGAL PUMPS

Summit 2196 / Summit Clark 3

SELF PRIMING PUMPS

ANSI CENTRIFUGAL PUMPS

ANSI CENTRIFUGAL PUMPS

Summit 2796 / Summit SN / Iwaki SMX

MAG DRIVE PUMPS

ANSI CENTRIFUGAL PUMPS

CENTRIFUGAL PUMPS

ANSI / ETFE / PFA / PP/ Stainless / Self Priming

CENTRIFUGAL PUMPS

CENTRIFUGAL PUMPS

CENTRIFUGAL PUMPS

Summit 2175 / Summit CC/FM / Summit SP Slurry / Summit DSR

GEAR PUMPS

MACHINERY GUARDING

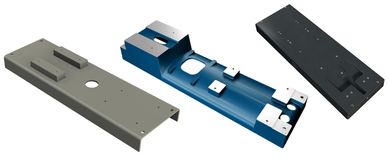

PUMP BASE PLATES

Summit VV40 / VV95

PUMP BASE PLATES

MACHINERY GUARDING

PUMP BASE PLATES

Fabricated Carbon or Stainless Steel / Cast Iron / Basetek Poxycrete

MACHINERY GUARDING

MACHINERY GUARDING

MACHINERY GUARDING

Coupling Guards / Frame Adapter Guards / Custom Guards / Stainless Steel / Aluminum / Plastic

CUSTOM FABRICATION

CUSTOM FABRICATION

MACHINERY GUARDING

Measurements and Design Also

ANSI CENTRIFUGAL PUMPS

Summit 2196 ANSI

Summit Clark 3 ANSI

Summit Clark 3 ANSI

Features

- Rear Pull-Out Design

- Efficient Interchangeable Parts, Goulds Replacement Parts, Durco Replacement Parts

- Capacities to 6000 GPM

- Heads to 730 feet

- Temperatures to 700 deg F

- Fully Open Impeller

- Extra Large Oil Sump

- Rigid Frame Foot

Applications

Water, Chemical, Oil, Pulp, and Paper, General Purpose Pump

Optional Features

- Finned-Tube Oil Cooler

- Multiple Stuffing Box Cover Options

- Standard Bore

- Large Bore

- Taper Bore

Summit Clark 3 ANSI

Summit Clark 3 ANSI

Summit Clark 3 ANSI

Features

- Conforms to ASME B73.1M (ANSI)

- Capacities to 5,000 GPM

- Head to 740 Feet

- Back Pull Out Design

- Threaded Bearing Housing, Durco Replacement Parts

- Accurate Impeller Adjustments

- Reverse Vane Closed Impeller

- Reduced Shaft Deflection

Applications

Water, Chemical, Oil, Pulp and Paper, General Purpose Pump

Optional Features

- Multiple Rear Cover Options

- Open Impeller Design Available

- Finned Tube Oil Cooler

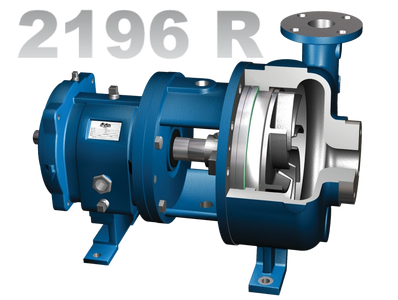

Summit 2196-R ANSI

Summit 2196-LF ANSI

Summit 2196-LF ANSI

Features

Utilizes your existing 2196 power end and ANSI bolt pattern

- Handles fibrous and shear sensitive materials

- Minimizes degradation of solids

- Available in 5 different sizes and a variety of materials, Goulds Replacement Parts

Applications

Paper & Pulp, Cleaners, Manure Transfer, Waste Water, Fruit Pulp

Optional Features

- Finned-Tube Oil Cooler

- Multiple Stuffing Box Cover Options

- Standard Bore

- Large Bore

- Taper Bore

Summit 2196-LF ANSI

Summit 2196-LF ANSI

Summit 2196-LF ANSI

Features

- Low Flow High Head Applications

- Radial Vane Impeller

- Balance Holes on Impeller

- Interchangeability with Existing ANSI Pump, Goulds Replacement Parts

- Rigid Frame Foot

Benefits

- Reduced Shaft Vibration

- Lower NPSHr

- Lower Seal Chamber Pressure

- Extended MTBF on Pump and Mechanical Seal

Applications

Additive Chemicals, Batch/Continuous Chemical Reactors, Chemical Dryers, Chemical Processes, Condensate Service, Evaporators, Petro Chemical Service, Shower Services

Optional Features

- Finned-Tube Oil Cooler

- Multiple Stuffing Box Cover Options

- Standard Bore

- Large Bore

- Taper Bore

Self Priming pumps

Summit 2796

Summit 2796

Summit 2796

Features

- Self-Priming

- Utilizes Existing 2196 Power End

- Rear Pull-Out Design

- External Axial Impeller Adjustment

- Open Non-Clogging Impeller

- ANSI Foot Pattern, Goulds Replacement Parts

- Extra Large Oil Sump

- Rigid Frame Foot

Applications

Bilge Water Removal, Industrial Sump, Chemical Transfer, Mine De-watering, Filter Systems

Optional Features

- Finned-Tube Oil Cooler

- Multiple Stuffing Box Cover Options

- Standard Bore

- Large Bore

- Taper Bore

Summit SN

Summit 2796

Summit 2796

Features

- Self-Priming Non-Clogging

- Capacities to 3,400 GPM

- Hard Faced Mechanical Seals Standard

- Standard Spool Piece Flanges

- Direct Drive or V-Belt

- Designed for Easy Maintenance

- Compact Removable Rotating Assembly, Goulds Replacement Parts

Applications

Sump or Bilge Pump, Mild Corrosives, Sewage, Pulp & Paper, Wineries, Fibrous Materials

Optional Features/Versions

- SN B: Utilizes 5 Vane Impeller

- SNS: Redesigned Version of the SN

- SNU: more Efficient Self-Primer Pump

Iwaki SMX

Summit 2796

Iwaki SMX

Features

- Quick Priming

- Capacities to 132 GPM

- Easy Maintenance

- Expanded Versatility

- Enhanced Durability

Applications

Sump Pump, Tank and Tanker Truck Transfer, Chemical Tank to Tank Transfer

Optional Features/Versions

- SMX(F) series mounts to NEMA C-faced motors allowing for limitless voltage and service choices.

mag drive pumps

Iwaki MDM ANSI

Iwaki MDM ANSI

Iwaki MDM ANSI

MDM is a wide ranging line of chemical process pumps designed to solve the most demanding chemical handling applications.

Max. Capacity: Up to 350 GPM

- Unexpected dry running won’t damage the pump or interrupt the process. Our dry run (carbon/ceramic) design allows the pump to handle these situations with

- An expanded temperature range (up to 300°F) as well as increased solids handling capabilities (up to 10%) provides users with solutions for their difficult applications.

- Two materials of construction and convenient mounting configurations allow MDM to handle many aggressive chemical and high purity applications.

- Installation and maintenance time are reduced with our compact, close-coupled design.

- Operating costs are reduced thanks to simple, modular construction and individually replaceable parts.

- Small, lightweight and perfectly concentric magnet capsules optimize pump efficiency.

- High strength rare earth magnets are totally encapsulated within fluororesin moldings.

- MDM’s back pull-out design allows the operator to inspect the pump while leaving the line pressurized. MDM’s modular design keeps your operating cost low over the life of the pump by making regular maintenance and periodic inspection a snap.

Iwaki MXM

Iwaki MDM ANSI

Iwaki MDM ANSI

The MXM series design offers the best combination of durability, safety and performance for a wide range of chemical process applications.

Max. Capacity: Up to 146 GPM

- Dry run capability – With proven dry run capability and our unique self-radiating bearing lubrication circuit (PAT.), the MXM is able to withstand process-upset conditions.

- Heat dispersion holes located strategically behind the impeller facilitate removal of frictional bearing heat and improve bearing lubrication and cooling circuit flow under dry run or poor suction conditions.

- Two piece rear casing design – Offers improved pressure handling capability and a second barrier for improved safety. The front casing features injection-molded liner with guaranteed uniform thickness and is fully covered by a ductile cast iron cover for combination of chemical resistance and mechanical integrity.

- All designs have ANSI 150# flanged connections.

- Dual end supported precision ground shafts and balanced compact high strength

- Samarium Cobalt magnet capsule result in balanced lightweight inner magnet capsule assemblies optimizing torque transmission and pump efficiency.

- High strength rare earth magnets are totally encapsulated within fluororesin moldings.

- Close-coupled back pull-out design – Allows the operator to inspect the pump while leaving the line pressurized.

Iwaki MDW

Iwaki MDM ANSI

Iwaki MP (Metallic)

The MDW Series are the largest fluoroplastic magnetic drive pumps in the world, offering high efficiency and durability for chemical process applications.

Max. Capacity: Up to 1320 GPM

- High discharge capacity, High head and high efficiency – The heavy-duty MDW is capable of a maximum discharge capacity of 5,000 L/min and max. discharge head of 98m, enabling applications in previously unexplored areas with a wide range of liquid specific gravities.

- Highly chemically resistant – Fluoroplastic and fine ceramic wetted parts offer high resistance to virtually every industrial chemical, regardless of concentration. ISO compliant – The MDW is dimensionally compliant with the international standard (ISO2858, 3661) and is interchangeable with conventional sealed centrifugal pumps.

- Robust structure – Use of the high strength ductile cast iron external armour is mandatory for heavy duty chemical process applications.

- High casing pressure resistance is achieved with a unique rear casing design preventing stress concentration and incorporating a triple-layer structure (PAT). A special metal shaft is used on the MDW to withstand high radial forces and allow continuous extended operation even under harsh service conditions.

- Back pullout system – The back pullout system allows easy maintenance and inspection without removing pipework. Integrated components and a sealed rear casing support structure enable motor removal safely without chemical leakage.

Iwaki MP (Metallic)

Iwaki MP (Metallic)

Iwaki MP (Metallic)

The MP Series is the perfect combination of dependability and affordability. With flow rates to 340 GPM and rugged 316 stainless steel construction, the MP Series meets most sub-ANSI applications at a very affordable price.

Max. Capacity: Up to 340 GPM

- Center bearing support prevents shaft deflection

- One piece machined rear casing provides extra strength

- High strength Neodymium or Samarium Cobalt magnets for higher temperatures

- Single gasket seal eliminates multiple leak paths

- Silicon Carbide -D bearings can withstand limited dry run

- NEMA motor provides endless motor options

- Removable impeller for easy maintenance

Iwaki MX

Iwaki MP (Metallic)

Iwaki MX

The MX Series pumps represent the latest state of the art design in plastic magnetic drive pumps. MX Series has been engineered to meet the most severe operating conditions.

Max. Capacity: Up to 225 GPM

- Self-radiating structure – When fitted with a carbon bearing, the MX will allow for brief periods of dry running. The new “self radiating structure” (patented), in addition to the existing proven non-contact principle with front and rear supported spindle, greatly improves the ability to withstand cavitation and running against a closed discharge valve.

- Split volute casing – The MX Series is the first resin magnet pump that uses a split volute pump casing that forms a vortex chamber. The volute limits the liquid flow from the impeller and returns it to the pump, which is efficiently guided to the discharge port to enhance overall efficiency.

- MX Series pumps are highly recommended for use in various production processes such as filtering, spraying, washing, plating, chemical transfer/blending, and etching in surface treatment applications.

- MX utilizes standard NEMA frame motors making them easy to install. (IEC and JIS versions available)

- Non-metallic baseplate will not corrode in hostile environments.

Iwaki MD

Iwaki MP (Metallic)

Iwaki MX

Iwaki America, the world leader in small magnetically coupled centrifugal pump technology, offers the premier line of non-metallic centrifugal pumps.

Max. Capacity: Up to 36 GPM

- High Efficiencies – Extraordinarily high efficiencies make WMD & MD the clear choice in almost every process, recirculation or transfer application.

- Choose standard alumina ceramic bearing materials and polypropylene, or optional SiC (silicon carbide) and ETFE (fluoropolymer) for your most aggressive or highest purity requirement.

- Do you require compact, quiet, highly efficient pumps for your Laser, Chiller or Blood Analyzer Applications? Iwaki America pumps are compact, offer higher pressure, AND last longer than any traditional offerings.

- Motor Matching – Offering more motor/pump configurations than any other manufacturer easily allows tailored pump applications. Premium, high efficiency motors are used throughout the line. Totally enclosed, permanent split capacitor motors are compact, cool and economical. Tolerance to voltage variation without overheating and 50/60 Hz operation allows the product to be used in a worldwide market. PSC or shaded pole AC motors are standard. Brushed and brushless motors are available for DC applications.

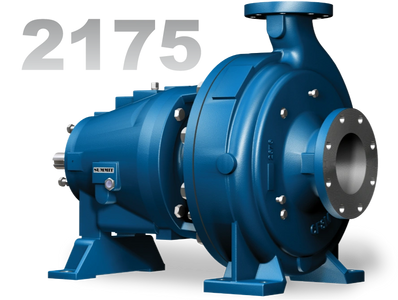

centrifugal pumps

Summit 2175 Pulp & Paper

Summit 2175 Pulp & Paper

Summit 2175 Pulp & Paper

Heavy Duty Process Pump

Features

- Rear Pull-Out Design

- Efficient Interchangeable Parts

- Sacrificial Wear Items

- Double Wall Volute on Larger Sizes

Applications

Pulp & Paper:

Cleaners, Filtrate, Liquor, Screen Reject

Steel:

Cooling Water, Descaling, Slurries, Tailings

Food:

Beet and Cane Sugar, Cane Juices, Fruit Pulp, Wet Corn Millings

General:

Manure Transfer, Mine Water, Waste Treatment

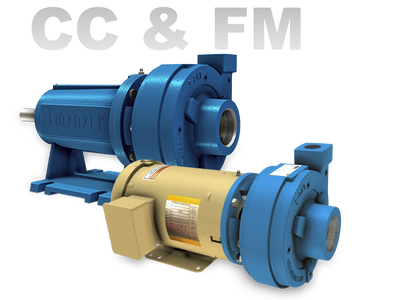

Summit CC/FM

Summit 2175 Pulp & Paper

Summit 2175 Pulp & Paper

Close Coupled & Frame Mounted

Features

- Capacities to 2,300 GPM

- Heads to 440 Feet

- Use of Minimal Space

- Interchangeable Parts

- Split Casing Design

- Sacrificial Sleeves and Rings

Applications

- Clean Water

- Solvents

- Light Oils

- Non-Corrosive Chemicals

- Coolants

- Brines

Parts

CC and FM pumps and parts manufactured by Summit Pump, Inc. are functionally and dimensionally interchangeable with the Peerless C & F line manufactured by Peerless Pump. Parts for part interchangeability means you have a quality option when sourcing pumps or parts.

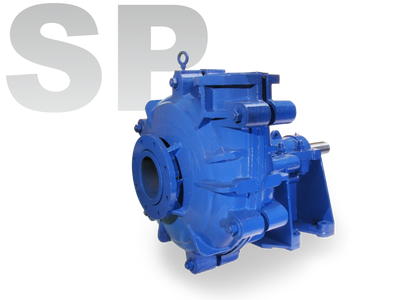

Summit SP Slurry

Summit SP Slurry

Summit SP Slurry

Slurry Pump

Features

- Heavy Duty Pumps

- Designed for Abrasive Applications

- High Chrome or Removable Rubber Wear Parts

- Packed Box Standard

- External Impeller Adjustment

- Capacities to 7,000 GPM

- Heads to 240 Feet

Applications

Waste Sludge, Paper Pulp & Wastes, Clay & Sand Slurries, Lime Mud, Dirty Water

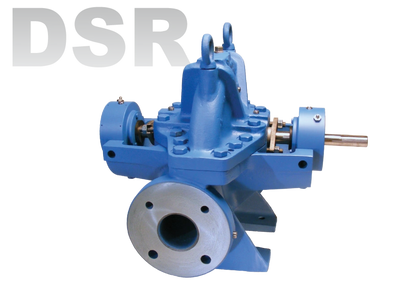

Summit DSR

Summit SP Slurry

Summit SP Slurry

Double Suction Pump

Features

- Capacities to 6,000 GPM

- Heads to 430 Feet

- Horizontal Split Case Design

- High Efficiency and Low NPSHr

- Closed Impeller

Applications

Oil and Gas, Cooling Water, Boilers, Sea Water, Mining, Chemical Process, Irrigation, Condensate Pump, Water Supply

Optional Features

- Replaceable Wear Rings, Variety of Materials

- Packing or Mechanical Seals

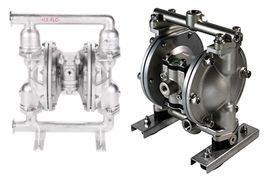

diaphragm pumps

All-Flo

Iwaki Air

Iwaki Air

Since 1986, All-Flo pumps have been built to last. Designed to live up to their name, All-Flo pumps are performance engineered and quality built to provide trouble-free service under the toughest conditions. All of our pumps are 100% factory tested for quality assurance. Our pump’s air mechanism features the fewest moving parts of any pump on the market. With fewer parts to wear and breakdown, the result is reduced risk of disruptions in service and reliable operation. When it comes to simplicity of design, see for yourself how our pump stacks up against competitors.

Iwaki Air

Iwaki Air

Iwaki Air

Iwaki Air AODD pumps are engineered for maximum utility. They are portable and easy to install, operate, and maintain. Infinitely variable flow rates and variable discharge pressures can handle a large range of fluids, including corrosive chemicals and flammable liquids. Iwaki Air AODD pumps can run dry, self-prime and dead-head without damaging the pump. Other design elements that distinguish Iwaki Air AODD pumps include body stabilization features to ensure heat resistance, and sound suppression construction to reduce both mechanical noise and compressed air noise. Most important, the lube-free air valve features a non-centering spring specially designed not to stall and is accessible for easy maintenance.

These pumps are built for power. A higher power output means the pump can operate with less applied air pressure compared with many competitor’s pumps – often outperforming pumps that may have a higher listed flow rate.

Iwaki Air

Copyright © 2025 Ndustrial Solutions - All Rights Reserved.